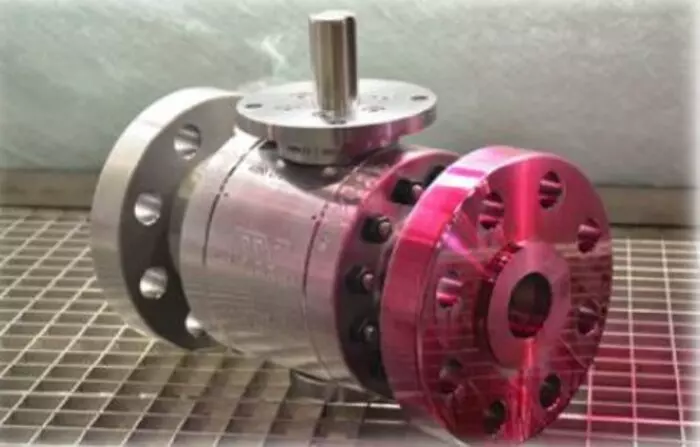

Dye Penetrant Inspection (DPI) is widely used to detect surface breaking flaws.

This non-destructive testing technique, also known as liquid penetrant inspection (LPI), is a cost-effective method used to locate surface breaking flaws such as cracks, porosity, laps, seams and other surface discontinuities. Dye penetrant inspection can be applied to both ferrous and non-ferrous materials and all non-porous materials (metals, plastics or ceramics). Our techniques for dye penetrant inspection include: